- |

- Contact Us |

Brochure

Brochure

PROJECT REPORT

Project reports works as a key for an entrepreneur for gathering

information on the subject, taking a planned decision on investments

or for submission to industrial departments/Financial firms. With

inhouse experts we can provide system details, cost estimate,

sensitivity analysis, pay back / ROI and overall road map for

execution. We offer services to financial institution for evaluation of

Proposal and provide a team of Experts for same.

We also offer our services to International clients looking for direct

investment in India and help them a jump start by giving information

on various statutory requirements and rule of the land. We also help

them get introduced to our associates for Legal and HR needs.

Case Study : Las successfully presented a report on 'Small Scale LNG Import & regas Terminal' for Lotus

Energy Solutions Pvt. Ltd, Banglore.

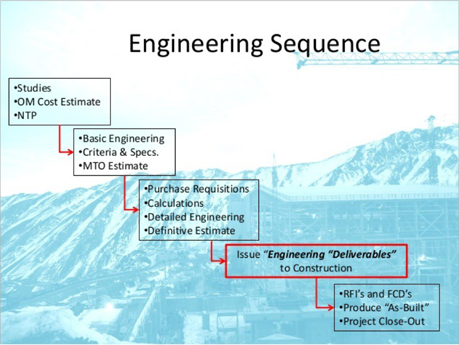

BASIC ENGINEERING

LAS offers complete range of services including static and dynamic

simulation, equipment process design, system sizing, optimisation and

debottlenecking services, utility calculations, etc.

For certain processes like

Cryogenic Storages, Paints and adhesives we provide complete basic

engineering packages. For other projects, we perform Extended Basic,

Engineering and Front End Engineering Design (FEED), using the Basic

Engineering Packages from the selected Licensor. In select cases, we have

the distinction of developing the complete Basic Engineering, based on

skeletal information from the concerned Licensors.

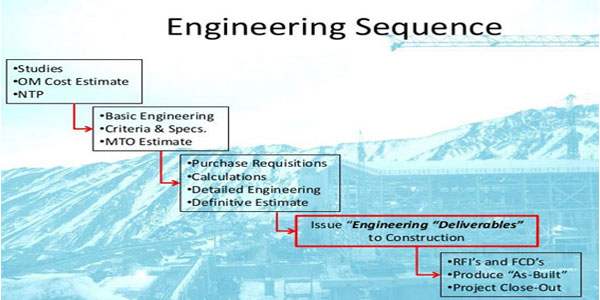

DETAILED ENGINEERING SERVICES

Las provides detailed engineering in all fields required for successful execution of project. Major roles are listed below. Along with design and detailed engineering the scope includes preparation of technical specications, RFQs (Requests for Quotation), tender document with specification for execution and documents required for statutory approvals.

- P&I DIAGRAM

- PLOTPLAN DEVELOPMENT

- EQUIPMENTLAYOUT

- MECHANICALDESIGN

- CIVIL& STRUCTURE

- PIPING

- ELECTRICAL

- INSTRUMENTATION

- DOCUMENT REVIEW AND APPROVALS

SPECIALITY SERVICES

Las has team of experts and have provided services as follows :

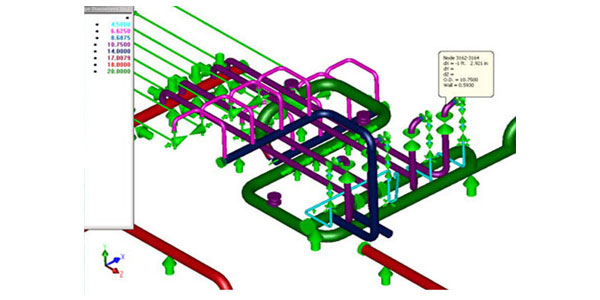

Stress Analysis

A pipe stress analysis (thermal flexibility analysis) will predict stresses in piping and loads on equipment resulting from thermal gradients, thermal transients, weights, pressure, and bolt-up strain. This study is typically required for piping that experiences high temperature fluctuations, or for long pipe runs. Cases where equipment is sensitive to external loads may also require a pipe stress analysis. We regularly carry out stress analysis for all stress critical lines for all our project using Caesar II software. Case study : We have carried out stress analysis of cross country for Propane / Butane from Jetty to Import terminal (250mm Nb x 9Km) for our Clients, Navana LNG Ltd, Bangladesh

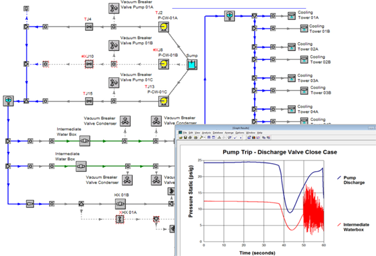

Surge Analysis

Surge Analysis is a flow assurance activity and refers to the analysis of pressure changes in pipework. It is usually undertaken on liquid pipelines where fluid compression is negligible and where sudden changes in flow velocity can cause over / under pressurisation of pipework. We carry out surge analysis for cross country lines using AFT Impulse software Case Study : We have also carried out surge analysis of cross country for 1100mm dia GRP, ~ 15Km cross country line from water reservoir to Relianace storage ponds for our client CPP. We have also carried out surge analysis for lines carrying cryogenic LPG & LNG.

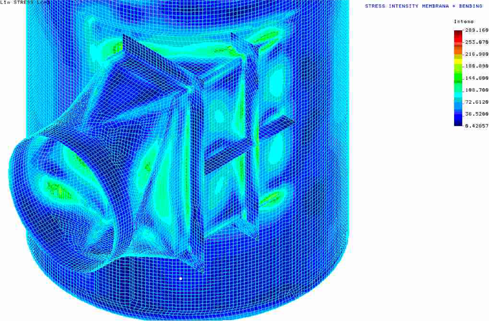

FEA(Finite element Analysis) & CFD (computational Fluid Dynamcs):

We carry out FEA for critical components and CFD as per project needs. Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Finite element analysis shows whether a product will break, wear out, or work the way it was designed. CFD is special case of FEA for fluids. Case Study : We have carried out FEM analysis for BARC, for vent gas scrubber handling radioactive waste using Cosmos software and qualified same as per ASME Section III subsection NC for SSE (safe shut down earthquake) and OBE (operation basis earthquake).

Process Development / Optimisation:

We help our client's to review and optimise their process and remove bottlenecks

for improving productivity. Same is achieved by detailed study of existing

process, static and dynamic simulation and equipment capacity simulation. We

can also offer services for development of process through our associates in

R&D organistaion.

Case Study: LAS successfully completed debottlenecking of Ammonium Nitrate Plant for

our client Deepak Fertilisers & Petrochemical Corporation Ltd. The original plant capacity

was 300TPD and nal achieved capacity was 500TPD. The complete plant simulation

and equipment sizing were checked. Only by adding few equipments and changing 10% of lines and fittings the

capacity increase was achieved.

We are having team of dedicated experts to take up special assignments for HSE, process optimisation,

SOPreview and security.

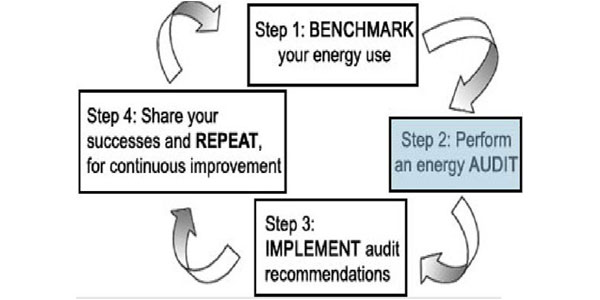

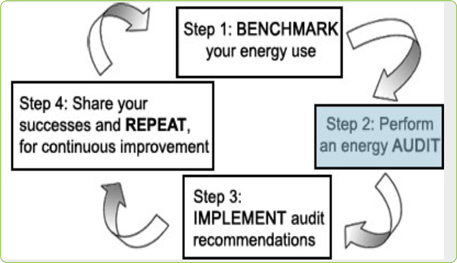

ENERGY & PRODUCTION AUDIT

An energy audit is an inspection, survey and analysis of energy flows, for energy conservation in a building, process or system to reduce the amount of energy input into the system without negatively affecting the output(s) Energy audit helps in energy cost optimization, pollution control, safety aspects and suggests the methods to improve the operating and maintenance practices of the system. It is instrumental in coping with the situation of variation in energy cost availability, reliability of energy supply, decision on appropriate energy mix, decision on using improved energy conservation equipment, instrumentations and technology. It has been established that energy saving of the order of 15 to 30% is possible by optimising use of energy by better housekeeping, low cost retro fitting measures and use of energy efficient equipment at the time of replacements. Our team of dedicated experts help you bench mark your energy consumption against industrial standards, review your existing process and give you analysis of possible optimisation in your process and give recommendation for better energy utilisation eg. change in source of energy eg. LPG or LNG or co- generation, etc..

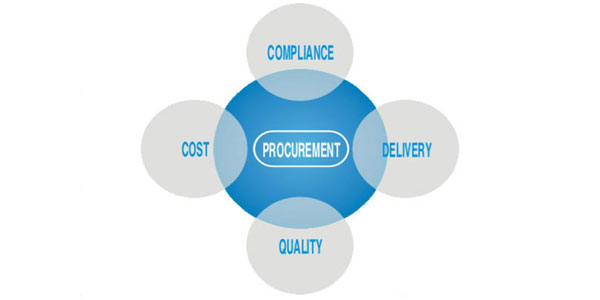

PROCUREMENT ASSISTANCE

For any project success, the sourcing of plant components and services is

the most important factor. LAS has developed a list of vendors and service

providers which are rated as per past experience. The same helps to nalise

the approved vendor list at start of project in consultation with the clients.

LAS helps to have smooth procurement activities including generation of

RFQ, review with vendors to bring everyone at par, bid analysis, technical

recommendation and commercial negotiations (if required). LAS inputs and

services continue even after order placement and our team is in continuous

touch with vendors for QAP and document approval, compliance with

manufacturing schedule & regular review meetings.

The same ensures

timely delivery and compliance to project requirements. We also assist our clients with E-bidding to make

the process more efcient and transparent.

INSPECTION SERVICES

LAS undertakes stage wise inspection services as per approved QAP by visting vendor shop and ensuring 100% compliance with enquiry specification. We also undertake expediting visits to ensure the vendor is following the manufacturing schedule as committed by him. All visit details are reported to client with status and possible concerns with suggestion on mitigation of same.

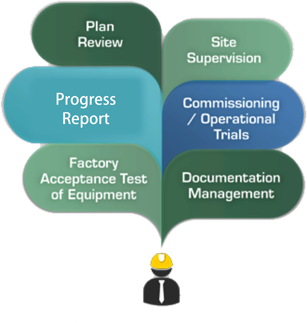

SITE SUPERVISION & COMMISSIONING ASSISTANT

LAS deputes teams of engineer for each discipline along with a project coordinator to

ensure all site execution is carried out as per the technical requirements. Regular site

meetings and review is organised and progress reports submitted to ensure strict

compliance with the project schedule.

The teams also helps in planning pre-

commisisoninng and commissioning activities .

The team also ensures highest safety

standards and HSE guidelines are adhered to.

PROJECT MANAGEMENT

LAS team provides complete project management services including preparation of detailed project schedule and updating, identifying milestones, bi-weekly and monthly project reports, following of project progress (S curve). The same ensures top management is well informed and has full control on the project activities.

GOVERNMENT APPROVAL & STATUTORY AUDITS

LAS also provides assistance for government approvals and statutory audits through its associates if needed by client.